PRODUCTION

Sustainability and craftsmanship are integral to the identity of MØY ATELIER and something that reflects in each finished MØY product. MØY takes pride in delivering unique designs and uncompromising quality, by marrying Japanese handcraft steeped in heritage with the most cutting edge and green technology.

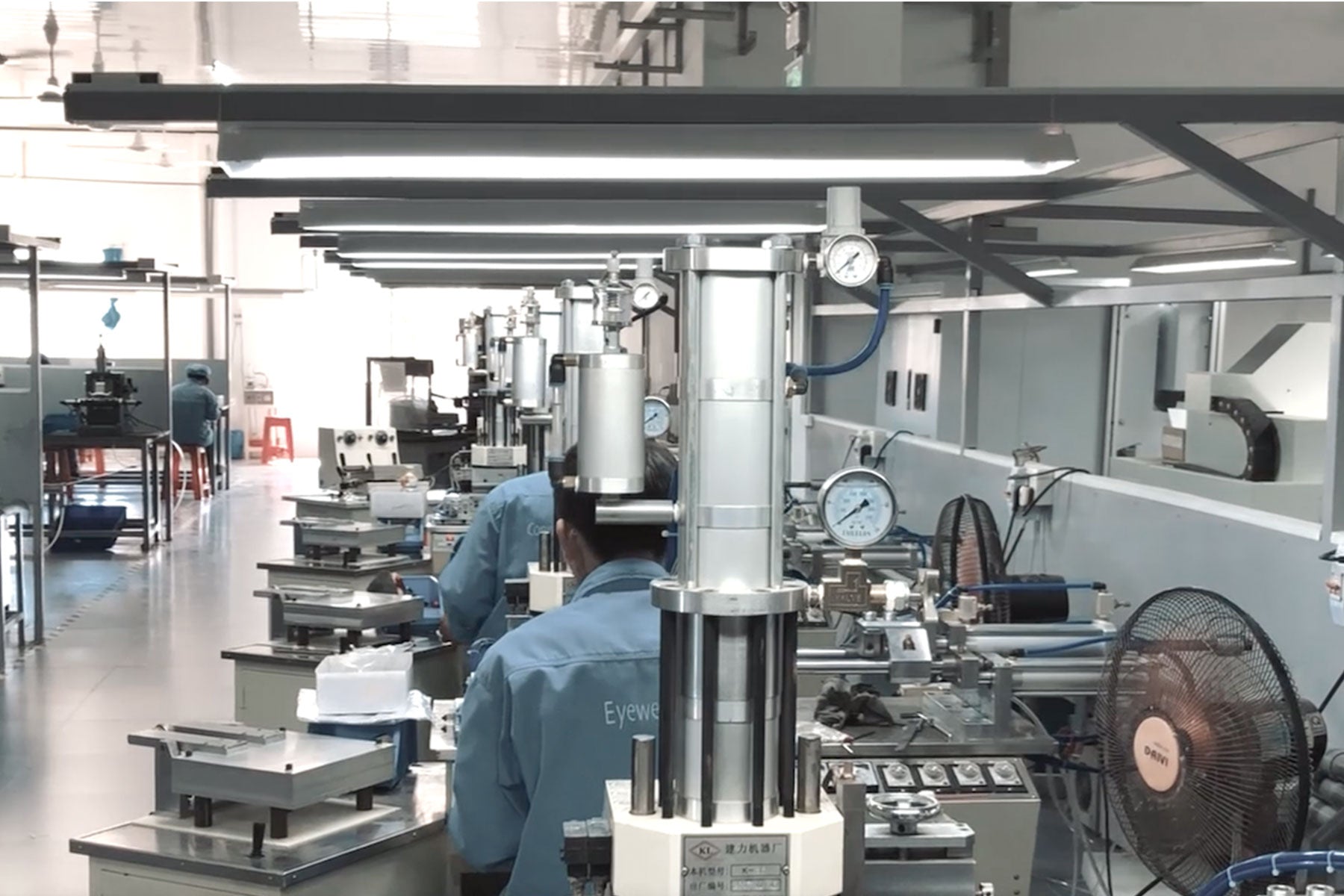

As an independent brand MØY keeps its production at the forefront of technological advancements beyond the traditional confinements of the eyewear industry by seeking out external partners that are in the trailblazers of green innovations. MØY are passionately committed to keeping our carbon footprint neutral by sourcing materials with the highest possible bio-based content, and that is 100% biodegradable and responsibly produce our products in a small and esteemed factory in Fukui, Japan. Our factory produces a limited quantity each year to ensure the integrity of the products. In essence, all our styles are limited editions.

Only a highly specialised factory has been able to satisfy our strict quality standards and cater to our complex and innovative design constructions. MØY’s chosen partner factory in Fukui, Japan is known for its exceptional attention to details and impeccable manufacturing methods, which stems from two centuries of accumulated knowledge and experience - ensuring that our designer sunglasses are of the highest standards of craftsmanship and ethical responsibility.

Each component is carefully chosen by MØY and then sent to our trusted factory in Fukui, Japan, where each pair of MØY sunglasses need attention and care to meet our strict standards of perfection. On close inspection, you’ll find that MØY sunglasses are always full of subtleties, details, and customised components that are fully unique to the brand. Features include finely worked gold metal detailing on the lens and temples, customised rim wires, concealed hinge designs, gold hot stamps, and signature embossed gold coin logo. A process that takes more than 200 stages. Skilled artisans craft each and every detail by hand. The polishing stage alone takes several days and ends with rigid quality control before the frame is shipped to London, UK.